The Evolution of Packaging

Packaging has evolved significantly from its original purpose of simply guarding products during conveyance. Traditionally, packaging prioritized continuity and visual appeal, but as requests have changed, so have consumer and manufacturer prospects. At the moment, packaging plays a vital part in branding, sustainability, and enhancing the overall consumer experience.

As businesses seek to meet the demand for faster and more effective services, the robotization of packaging processes has come essential. These represent a significant advance in this regard, allowing companies to easily and directly package products.

What are Bagging Machines?

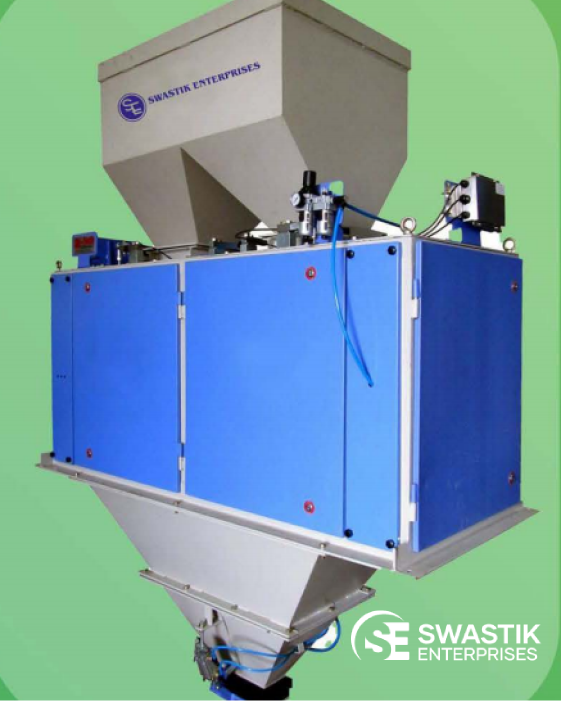

These are sophisticated systems designed to streamline the packaging workflow. These machines automate the processes of stuffing, sealing, and labeling bags, significantly cutting down on homemade labor and boosting affairs. They’re protean enough to handle a variety of accouterments effectively.

Equipped with advanced technologies similar to detectors, control systems, and robotics, bagging machines operate with minimum mortal intervention. They can accommodate different bag sizes and types, furnishing manufacturers with the inflexibility they need. Their capability to integrate seamlessly with being product lines further enhances their value, making them a critical element of ultramodern packaging operations.

Advantages:

Enhanced Efficiency:

These significantly improve the efficacy of the product. By automating repetitive tasks, these machines reduce the time required for packaging, helping companies meet tight deadlines while adding to the overall case.

Consistency and Accuracy:

Homemade packaging can affect inconsistencies in bag weight and sealing quality. These insure uniformity across all packages, which is essential for maintaining brand character and complying with nonsupervisory norms. Their perfection also minimizes waste by icing that each bag is filled directly.

Cost Savings:

Although the initial investment in these may be high, they offer long-term savings. By reducing labor costs through dropped primer quilting, these machines lead to lower functional charges. Likewise, lower product waste translates to significant savings.

Improved Safety:

In sectors similar to food and medicinal, safety is consummate. These overcome the impurity losses associated with home runs. Also, numerous machines come equipped with safety features that cover drivers, contributing to a safer working terrain.

Sustainability:

As companies focus less on sustainable practices, these can play an important role. Many models are designed to use eco-friendly packaging materials, and their effectiveness can translate into reduced energy consumption and waste generation. This commitment to sustainability can enhance a company’s brand image and attract environmentally conscious consumers.

Applications Across Industries

These are protean and applicable in colorful sectors, including:

- Food and Beverage: In the food assistance, speed and hygiene are pivotal. automatic bagging machines can efficiently package a wide array of products, from snacks and grains to frozen goods, while icing compliance with strict food safety regulations.

- Pharmaceuticals: Accuracy and adherence to strict guidelines are essential in pharmaceutical packaging. These ensure proper dosing and secure sealing, minimizing impurity loss.

- Chemicals: The chemical assiduity frequently requires careful packaging of dangerous accouterments . An automatic packing machine can handle these substances safely and effectively, reducing slip pitfalls and worker exposure.

- Retail: Aesthetic packaging is important in retail. These machines not only fill and seal bags but also offer options for custom labeling and branding, enhancing the consumer experience.

The Future of Packaging Technology

As technology advances, the future of packaging looks promising. Then are some trends to watch in the realm of these machines:

- Smart Automation: The integration of IoT (Internet of Effects) technology in these machines is expected to increase. Smart machines can cover product criteria in real- time, enabling prophetic conservation and minimizing time-out.

- Sustainability inventions: Adding to the pressure to adopt sustainable practices, in the future they will probably be designed to work with biodegradable accouterments and reduce waste during the packaging process.

- Customization: As consumer preferences shift towards substantiated products, the demand for customizable packaging results is on the rise. These machines that allow easy adaptations to bag sizes, shapes, and designs will be decreasingly sought after.

- Enhanced Robotics: Advances in robotics will lead to indeed lesser effectiveness in these machines. bettered robotic arms and handling systems will grease briskly and more precise packaging processes, boosting overall productivity.

- Data- Driven Decisions: As businesses collect further data on their packaging processes, there will be a shift towards data- driven decision- timber. These machines equipped with analytics tools will help manufacturers optimize their operations, reducing costs and perfecting quality.

Conclusion:

The future of packaging is nearly linked to advancements in these machines. As businesses aim to enhance effectiveness, cut costs, and borrow further sustainable practices, these machines will be vital in shaping the packaging geography.

At Swastik Enterprises, we understand the significance of these inventions in packaging technology. By investing in automatic bagging machines, companies can stay ahead of the competition, icing they meet the ever- evolving demands of consumers and nonsupervisory norms. The trip towards a more effective, sustainable, and precise packaging process is just beginning, with these machines leading the way.